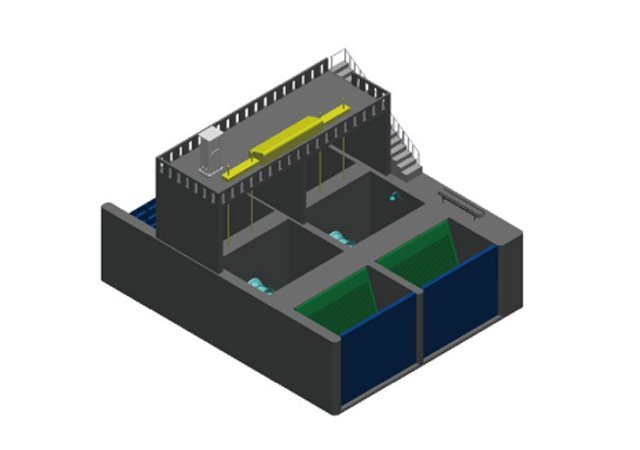

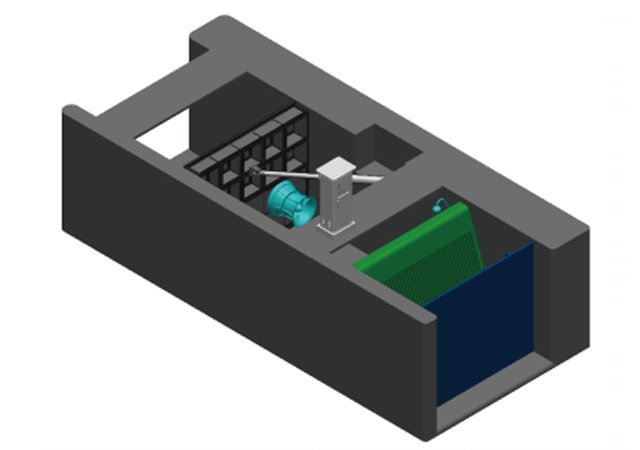

The integrated pump gate produced by Shanghai Kaiquan is a new type of water conveyance and interception system equipment, which adopts a new design concept and is based on a gate structure. The pump and gate are combined into one, and a control system and other auxiliary facilities are provided to achieve automatic control of river water bodies.

This system consists of working gates (including submersible pumps), hoists, electrical control systems, liquid level monitoring systems, and accessories such as maintenance gates and sewage grilles. It is widely used in watershed water diversion and river management projects.

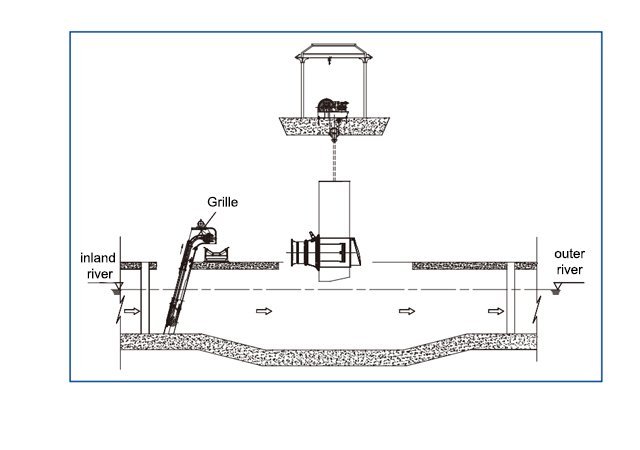

Artesian drainage

When the water level of the inner river rises to the set level and it is detected that the liquid level of the outer river is lower than that of the inner river, the working gate is opened, and the water flows by gravity.

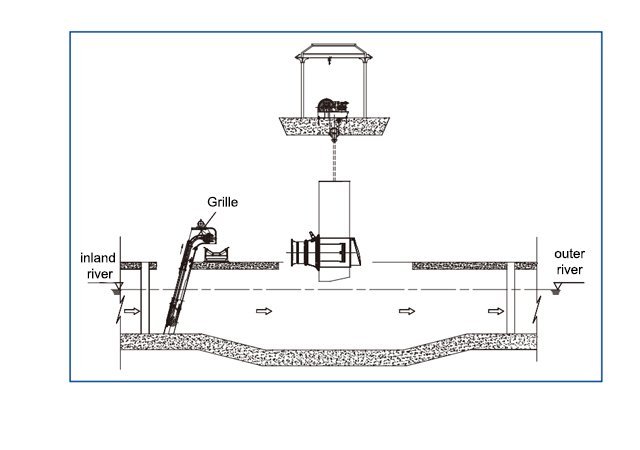

Forced drainage

When the water level of the inner river rises to the set level and the liquid level of the outer river is detected to be higher than that of the inner river, close the working gate, open the submersible pump, and forcibly discharge the waterlogging into the outer river.

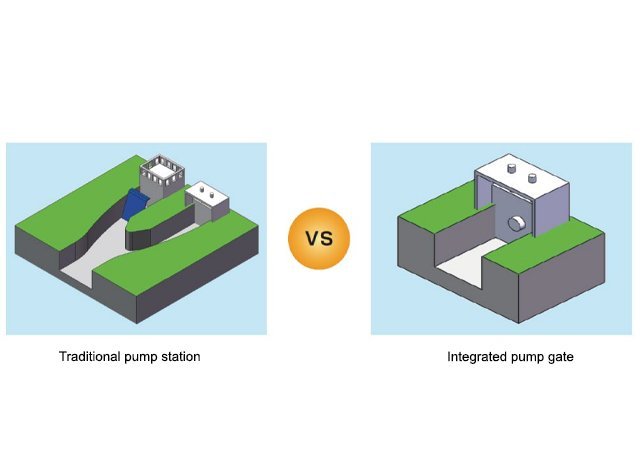

Traditional pumping stations VS Integrated pump gate

☆ Land saving and compact structure

The integrated pump gate creatively integrates the submersible pump and gate design, saving pumping station land, shortening project cycles, and reducing construction costs.

☆ Rigid structure, sturdy and reliable

The gate and pump barrel are welded as a whole using steel material. After FEA analysis, various loads such as water pressure, self weight, opening and closing force, and pump operation vibration are comprehensively considered to ensure stable and reliable operation.

☆ Smart management and unmanned control

Equipped with a dedicated control system independently developed by Kaiquan, it monitors the pump operation status in real time, collects and records operation data, uploads it to the central control intelligent cloud platform, and realizes real-time monitoring and alarm through mobile SMS through the Internet.

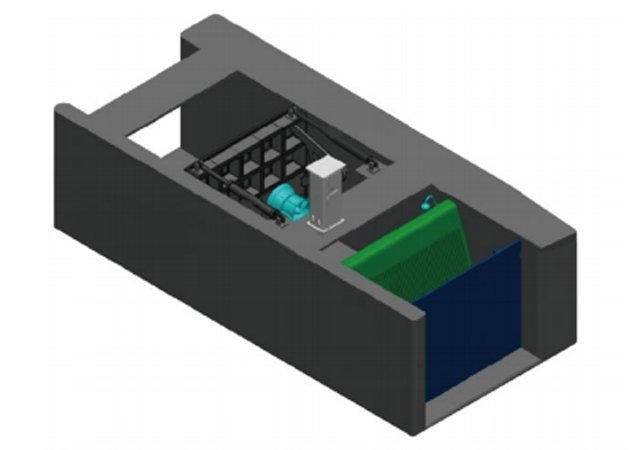

Unique shock absorption technology

1) Design to reduce the axial length of the pump and the cantilever length outside the gate;

2) The pump is rigidly connected to the gate and equipped with shock-absorbing pads;

3) Adding auxiliary support at the motor end effectively improves support protection during pump operation;

4) Modal analysis calculates the first-order natural frequency of the pump and gate, making the difference between them significant and reducing mutual influence

Lower pump stop liquid level

1) Excellent impeller hydraulic design reduces the cavitation margin of the pump, effectively reducing the submergence depth of the pump and lowering the pump shutdown liquid level;

2) Optimize the design of the water pump structure, minimize the installation height of the water pump on the gate as much as possible, and lower the pump stop liquid level.

Dredging and flushing technology

1) The bottom sill of the gate is equipped with a flushing pipeline and a small sewage pump for flushing the silt and sand that hinder the sealing of the gate;

2) A sewage interception tank is set at the bottom of the inlet of the pump gate to block the sedimentation of sediment entering the inlet. At the same time, a small sewage pump is equipped to regularly extract sediment from the sewage interception tank;

3) A mud blocking platform is installed at the inlet of the pump gate to prevent sediment from settling near the pump inlet.

Gate sealing technology

1) Using high-quality non-metallic rubber, fully complying with the technical requirements of HG/T3096 standard;

2) Professional installation ensures that the verticality and levelness of each waterproof seal meet the requirements of GB14173, and prevents premature damage to the waterproof friction caused by surface problems of embedded parts;

3) Professional structural design can enhance the sealing performance of water seals by leveraging water pressure.

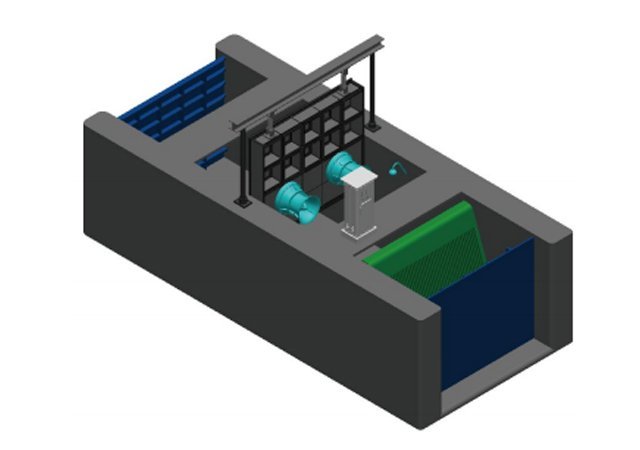

Specially matched axial flow pump or full through flow pump

Equipped with newly improved axial flow pumps or full through flow pumps, it has the following advantages:

1) Large flow rate, low head, suitable for drainage irrigation and other working conditions. At the same time, the wet stator full flow pump can provide bidirectional water delivery function, making it easy for users to control the water level inside and outside the river, achieving a combination of storage and drainage;

2) Reduce the axial length design, improve the cable outlet method, and effectively increase the convenience of on-site installation;

3) Set up various leakage and temperature sensors to prevent the water pump from continuing to operate in case of potential hazards and protect the water pump.

System design capability

The entire pump gate system has undergone CAE finite element strength analysis, taking into account various working conditions comprehensively

The vibration, hydraulic impact and other loads ensure that the strength and stiffness of the entire system meet the requirements for use

At the same time, the system also simulates the flow state of the river through CFD hydraulic analysis, optimizes the suction conditions of the water pump, and improves operational efficiency.

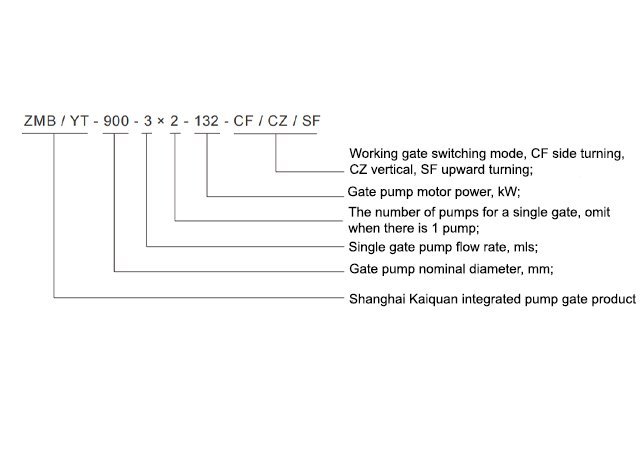

Flow rate: 0.3~6m3/s

Lift: 0.3-10m

Motor power: 11-400kW

Pump outlet diameter: 300-1200mm

Installation methods: vertical takeoff and landing (including top lift), upward flip, and side flip installation

1) Vertical take-off and landing of the gate (equipped with winch or screw hoist)

The working gate adopts a flat fixed wheel or flat sliding type. The pump is installed horizontally or vertically on the gate. The pump lifts and falls together with the working gate, and the lifting and lowering actions are performed by a winch or a screw hoist.

2) The gate is installed vertically (with hydraulic hoist)

The working gate adopts a flat fixed wheel or flat sliding type. The pump is installed horizontally or vertically on the gate. The pump takes off and falls together with the working gate, and the hydraulic hoist performs the lifting and lowering action.

3) The gate is installed by flipping up and down (equipped with hydraulic hoist)

The working gate adopts a flat sliding type, and the pump is installed horizontally on the gate. The pump takes off and falls together with the working gate, and the hydraulic hoist performs the up and down flipping, lifting and landing actions.

4) The gate can be installed by flipping left and right (equipped with hydraulic hoist)

The working gate adopts a flat sliding type, and the pump is installed horizontally on the gate. The pump opens and closes together with the working gate, and the hydraulic hoist performs the left and right flip switching action.

Main supply details of a single pump gate:

| Serial Number | Name | material quality | Quantity | notes |

| 1 | Submersible axial flow pump/full through flow pump | selection based on operating conditions | selection based on operating conditions | |

| 2 | Working gate | Select according to working conditions | Select according to working conditions | Equipped with door slot embedded parts and bottom sill embedded parts |

| 3 | Opening and closing machine | Select according to working conditions | Select according to working conditions | There are three types in total (winch, screw, liquid) Pressure), supply according to the selection results. |

| 4 | Control cabinet | Shell 304 stainless steel | Select according to working conditions | Including 2 sets of input level gauges |

| 5 | Clap the door | Select according to working conditions | Same as the number of pumps | Floating box or rollover type |

| 6 | Maintenance of stacked beam gate | Select according to working conditions | 2 sets per gate hole | Optional components |

| 7 | Trash barrier grille | Select according to working conditions | Select according to working conditions | Optional components |

| 8 | Rotating grille | Select according to working conditions | Select according to working conditions | Optional components |

Explanation: 1) Numbers 1-5 are mandatory equipment for each set of pump gates, and it is not acceptable to purchase only user provided service gates and other accessories for submersible pumps;

2)Choose either number 7 or 8 according to customer requirements.

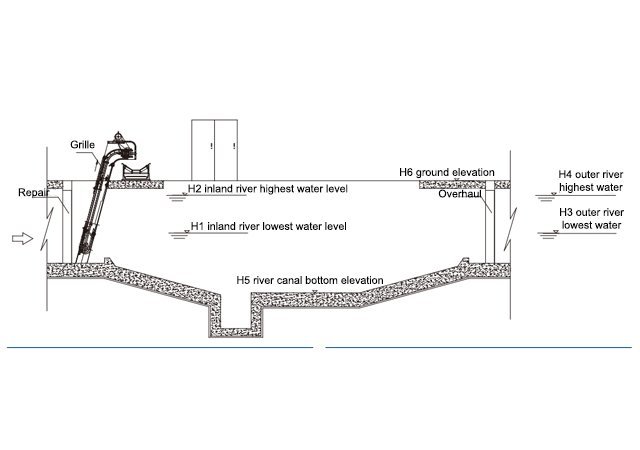

When users submit procurement requests, please provide the following information:

| installation drawing | performance parameter | ||

| The lowest liquid level elevation of the inland river H1 (m) | System flow rate (m ³/ S) | ||

| The highest liquid level elevation in the inland river is H2 (m) | Single hole flow rate (m) ³/ S) | ||

| The lowest liquid level elevation of the outer river is H3 (m) | Head (m) | ||

| The highest liquid level elevation of the outer river H4 (m) | Voltage level (V) | ||

| River channel bottom elevation H5 (m) | Motor power (kW) | ||

| Ground elevation H6 (m) | |||

| Total width of river channel L (m) | |||

| Gate single hole width (m) | |||

| System accessories | |||

| Rotating grille | |||

| Installation angle | Grid gap (mm) | ||

| Control method (time or liquid level difference) | Slag discharge height (mm) | ||

| Ordinary trash grille | |||

| material quality | Grid gap (mm) | ||

| Maintenance of stacked beam gate | |||

| material quality | |||

Send Your Inquiry Today