2BEX series water ring vacuum pumps and compressors are high-efficiency and energy-saving products developed by our company based on years of scientific research results and production experience, combined with the advanced technology of similar international products, and market research and analysis.

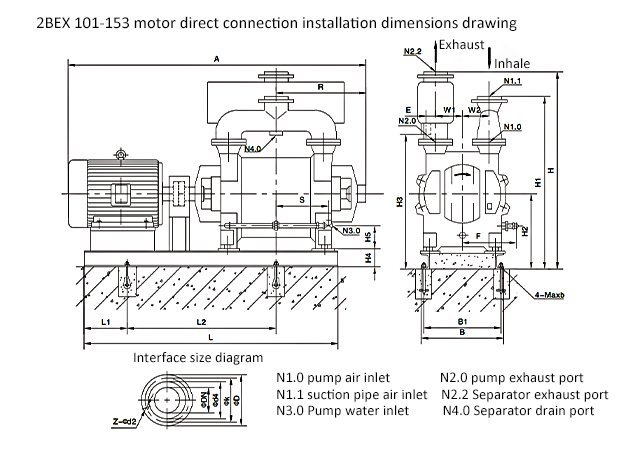

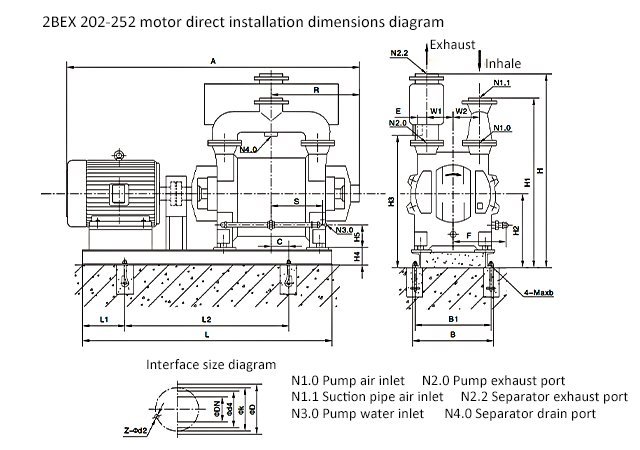

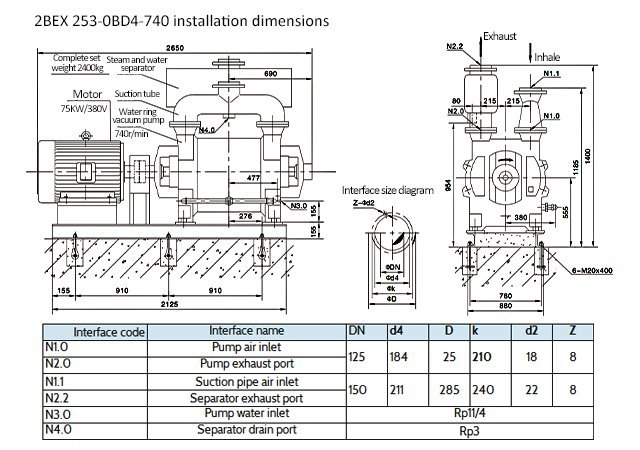

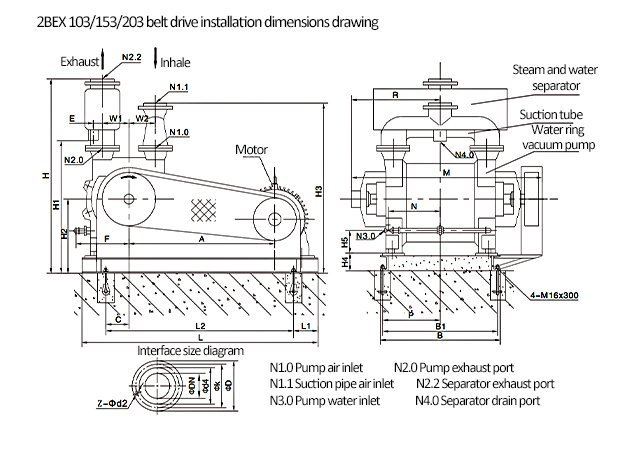

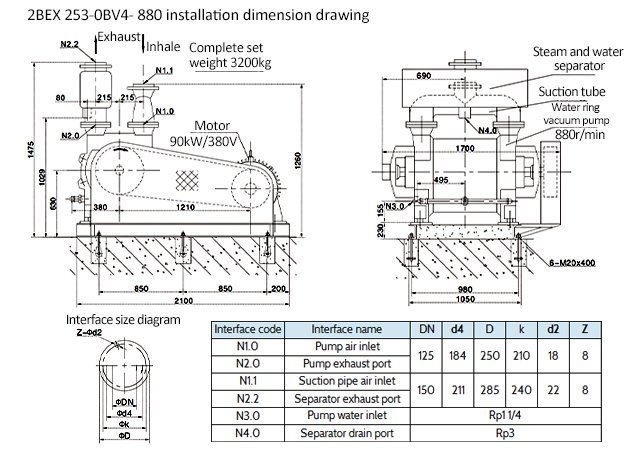

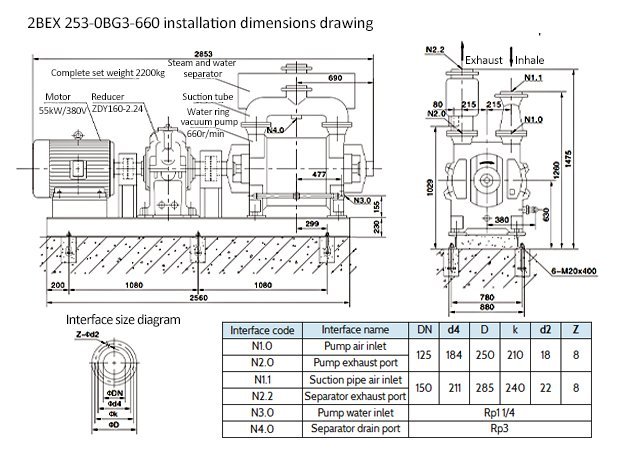

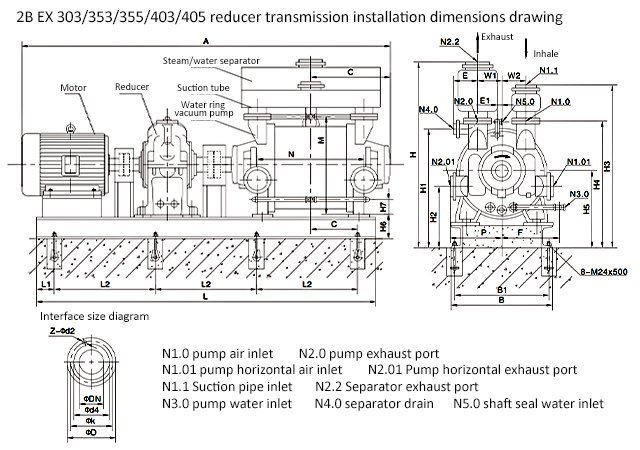

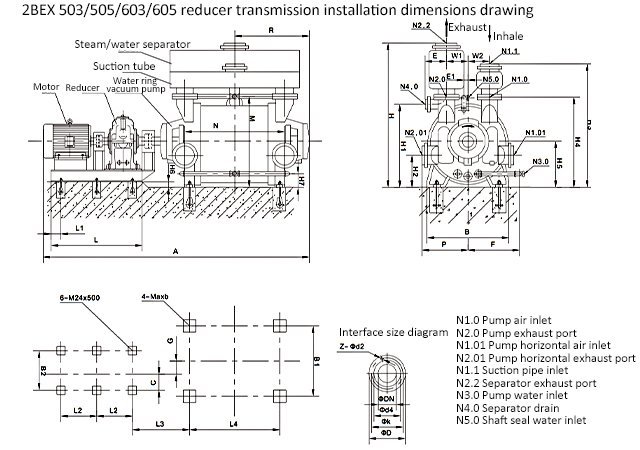

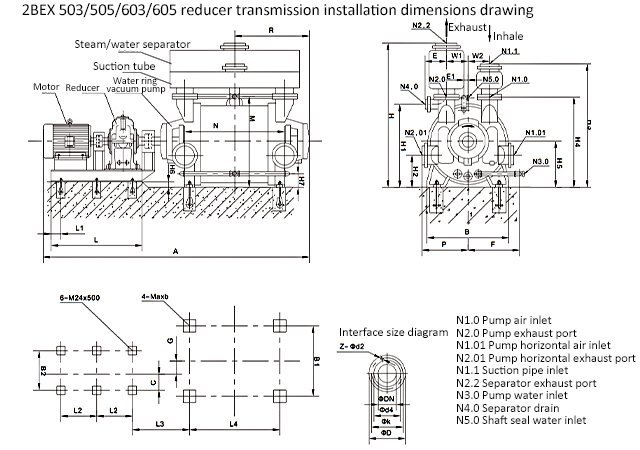

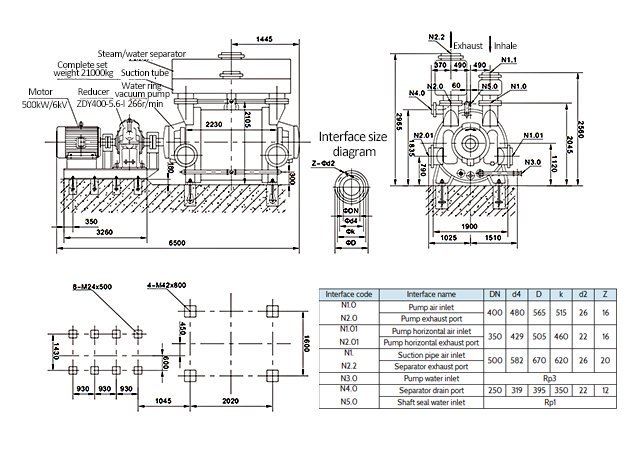

2BEX series water ring vacuum pumps and compressors use normal temperature clean water as the working medium and adopt a single-stage single-action structure. They have the advantages of simple structure, reliable operation, high efficiency and energy saving, and can adapt to harsh working conditions such as large displacement and load impact fluctuations. The pump unit has a horizontal structure, which is convenient for users to install and maintain. According to user needs, there are direct drive, pulley drive and reducer drive.

The products are carefully manufactured and have perfect quality control, reaching the leading domestic level. Our company has obtained IS09001 quality certification, and product quality is fully guaranteed. This series of products implements the JB/T7255 standard.

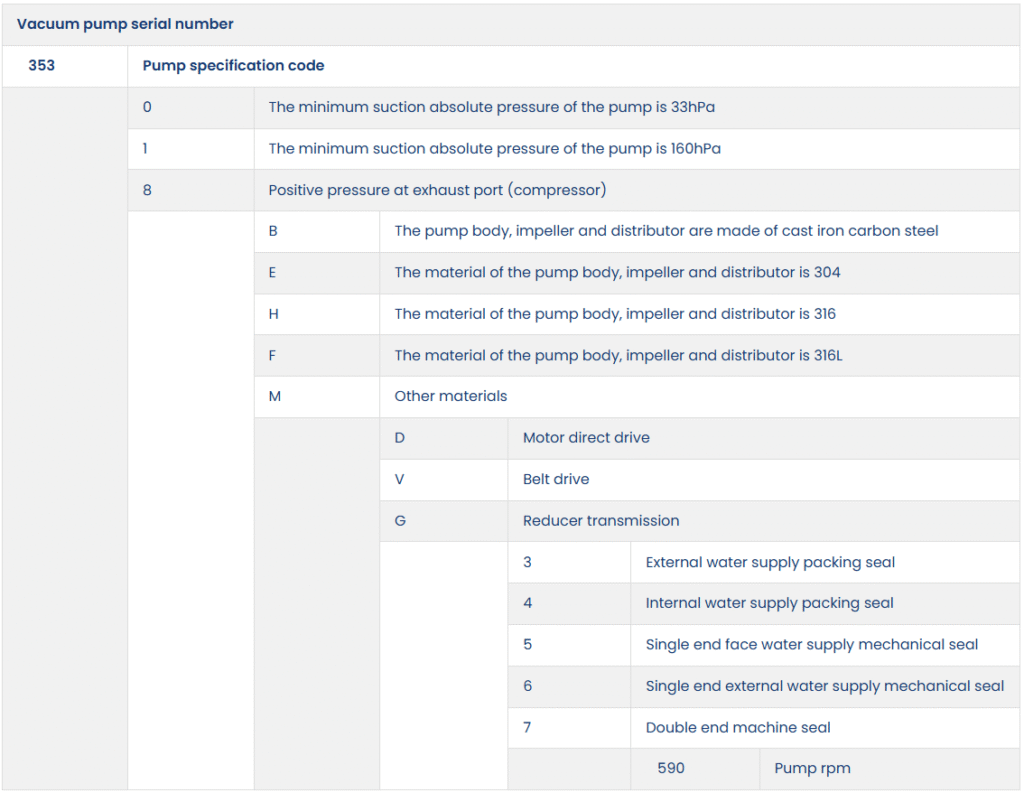

Model example: 2BEX353-0BD4-590

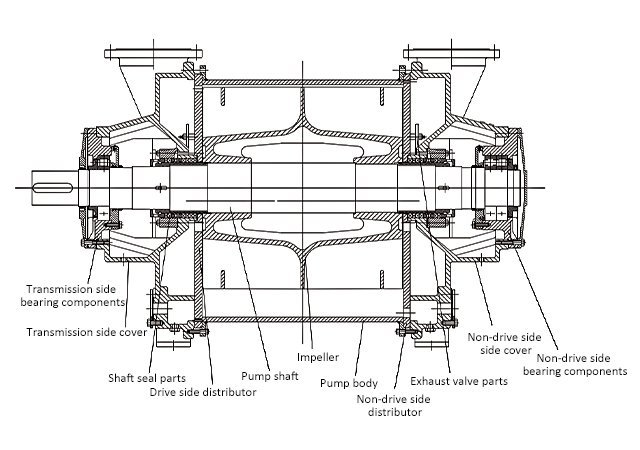

▲Single-stage single-action, axial intake and exhaust, simple structure and easy maintenance.

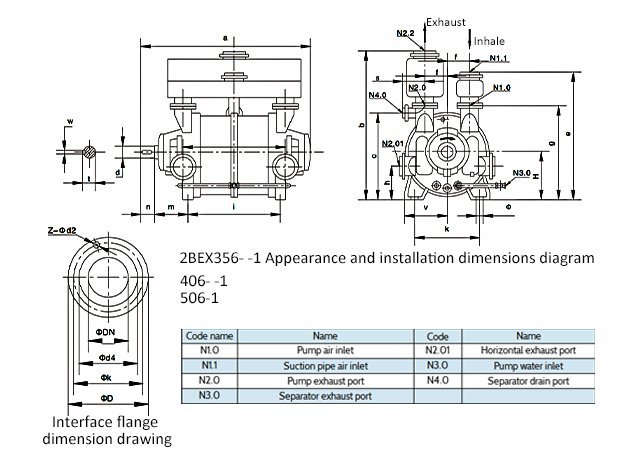

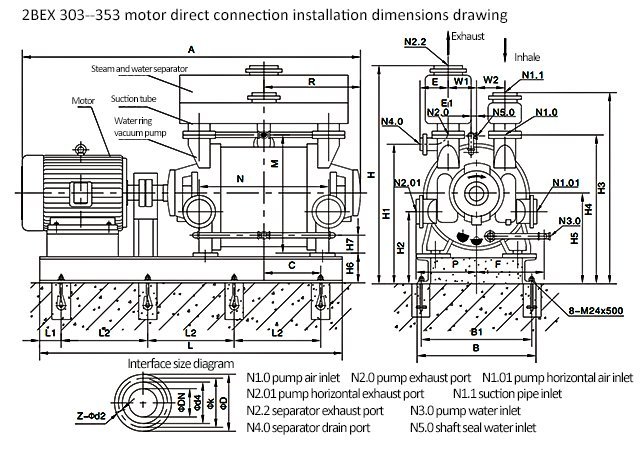

▲The large-diameter pump is equipped with both a horizontal exhaust port and a vertical exhaust port for user convenience.

▲ Equipped with an automatic drain valve to control the starting liquid level of the pump to avoid overload starting.

▲The rotor gap adjustment mechanism can accurately ensure the gap between the impeller end surface and the distributor surface, thus ensuring the performance of the pump.

▲The exhaust port equipped with a flexible valve plate can automatically adjust the exhaust angle, allowing the pump to operate efficiently under different suction states.

▲The impeller end face adopts a stepped design, which reduces the sensitivity of the pump to dust and water scaling in the medium. The large-sized impeller has an improved impeller reinforcement ring structure to prevent impurities from being retained and improve the impact of scaling on the pump. The pumped gas is allowed to contain non-granular dust.

▲The packing gland has a half-part structure and can be removed as a whole, making it easier to replace the packing.

▲By adjusting the assembly angle of the sealing box body, the functions of internal circulation and/or external supply of cooling water to the sealing box can be realized to meet different shaft seal needs. The small size pump has two types of shaft seals: packing and mechanical seal.

▲The shaft seal is equipped with a chromium steel protective sleeve.

▲The axial and radial loads of the pump are borne by two different sets of bearings, ensuring that the pump can operate continuously and reliably for a long time.

▲When equipped with a heat exchanger, the working fluid can be recycled and water loss is reduced. Through the self-priming function of the vacuum pump, the cooled working fluid is introduced into the pump without the need for a separate booster device.

▲The pump body structure with partitions allows one pump to adapt to the use requirements of two different working conditions.

Note:

This product is widely used in industrial sectors such as papermaking, cigarettes, pharmaceuticals, sugar refining, textiles, food, metallurgy, mineral processing, mining, coal washing, fertilizers, oil refining, chemical industry, electric power and electronics. Used for vacuum evaporation, vacuum concentration, vacuum resurgence, vacuum impregnation, vacuum drying, vacuum smelting, vacuum cleaning, vacuum handling, vacuum simulation, gas recovery, vacuum distillation and other processes. It is used to pump insoluble in water, non-containing The solid particles of gas create a vacuum in the pumped system. Since the pumping of gas is isothermal during the working process, and there are no metal surfaces that rub against each other in the pump, it is very suitable for pumping gases that are flammable, explosive or easily decomposed when the temperature rises.

Send Your Inquiry Today