The diesel engine driven water pump unit produced by Shanghai Kaiquan Pump Industry Group Co., Ltd. is developed and designed in accordance with relevant domestic and foreign standards.

In important water supply situations such as cooling circulation and boiler water replenishment, when there is a power supply failure, or when the power supply is normal but the electric pump cannot be put into use due to its own failure, this diesel engine pump can be automatically put into operation to ensure normal water supply and ensure the safety of life and property.

The equipment is technologically advanced and highly automated Due to its superior performance, complete protection functions, reasonable structure, easy installation, and high cost-effectiveness. This system is equipped with various automatic control functions to ensure that the unit can stand by normally for a long time and be put into operation at any time.

Diesel emergency pumps are used in large area and space fire water supply systems such as aircraft maintenance depots, petrochemical oil and gas depots, and thermal power plants; Emergency water supply system for high-risk equipment such as smelting furnace circulating cooling and boiler water replenishment.

Environmental atmospheric pressure>90kPa

Environmental temperature 5C-40℃

Air relative humidity ≤ 80%

The unit adopts single stage double suction pumps, boiler feedwater pumps and other pump types, with a wide range of flow and pressure.

When the water pump unit receives remote control instructions, or signals such as power outage or electric pump failure (start), the unit will automatically start and operate. The equipment has automatic program process control, automatic data acquisition and display, and automatic fault diagnosis and protection.

Display the current status and parameters of the equipment based on its actual operating conditions. The status display includes starting, running, accelerating, decelerating, (idling, full speed) stopping, etc. Process parameters include speed, oil pressure, water temperature, oil temperature, battery voltage, cumulative operating time, etc.

Start failure alarm, low oil pressure alarm and shutdown, high water temperature alarm, high oil temperature alarm, low battery voltage alarm, low fuel level alarm, overspeed alarm and shutdown.

On-site manual start stop control, remote start stop control from the control center, and starting operation after power outage.

Operation indication, startup failure, comprehensive alarm, control power supply closure, and other status feedback signal nodes.

During normal standby, the control system automatically charges the battery by floating. When the machine is running, the diesel engine’s built-in charging generator will charge the battery.

When the flow rate and head of the water pump do not match the actual requirements, the rated speed of the diesel engine can be adjusted.

When one set of batteries fails to start, it will automatically switch to another set of batteries (optional).

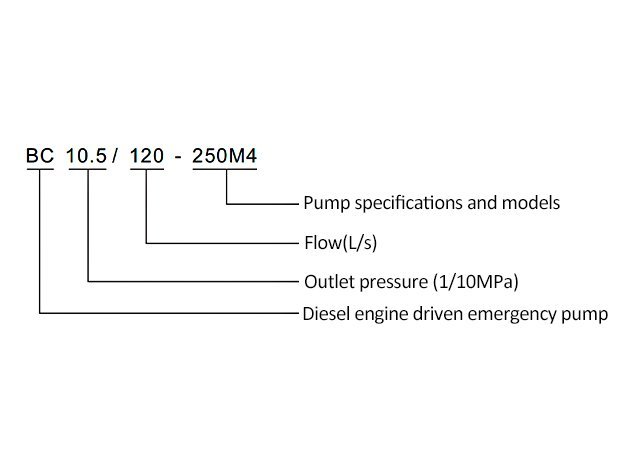

Horizontal single-stage open double suction centrifugal pump (KQSN), horizontal multi-stage boiler feedwater pump (DG)

The diesel engine driven water pump units produced by Shanghai Kaiquan Pump Industry (Group) Co., Ltd. are powered by well-known domestic and foreign brands of diesel engines, with priority given to products with high performance, high reliability, strong load capacity, and low pollution emissions. This series of products usually uses diesel engines from companies such as Wuxi Power, Chongqing Cummins, Dongfeng Cummins, IVECO, and Xichai, with speeds of 990r/min, 1500r/min, and 2900r/min.

The primary cooling method for the emergency pumps of all BC diesel engines in our company is closed water cooling. The secondary cooling methods include fan water tank cooling and heat exchanger cooling. The hot water generated during the operation of the diesel engine flows from the outlet pipe of the diesel engine to the heat exchanger, and the cold water in the cooling pipe of the heat exchanger cools the circulating hot water of the diesel engine. The circulating hot water of the diesel engine is cooled and then returned to the diesel engine, And cool down the diesel engine

The cold water inside the cooling pipe of the heat exchanger rises in temperature after cooling the circulating hot water of the diesel engine, and is pumped to the cooling tower for cooling. After cooling, it is sent to the cooling pipe of the heat exchanger.

The diesel engine and water pump of this product are generally directly connected by an elastic sleeve pin coupling, which has the characteristics of easy installation, low cost, small volume, reliability, and safety. For diesel engines that do not match pump speeds or when using a long shaft pump, a reducer or angle gearbox coupling is required. The cooling method of the reducer and gearbox should be considered, and the cooling method should not be a cooling method that requires power supply.

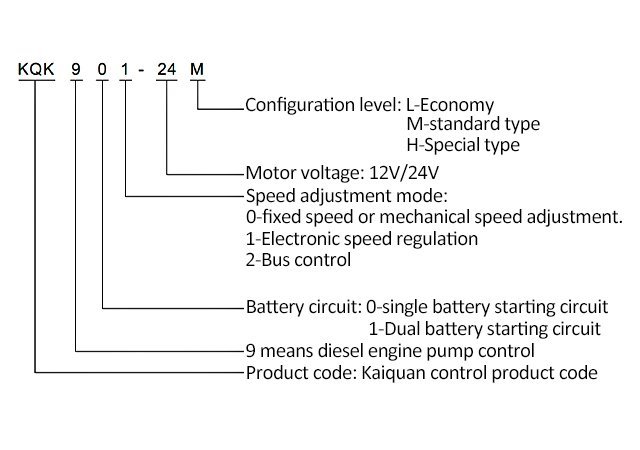

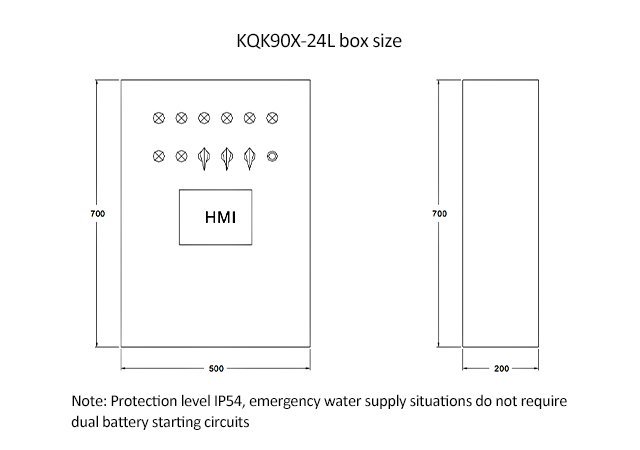

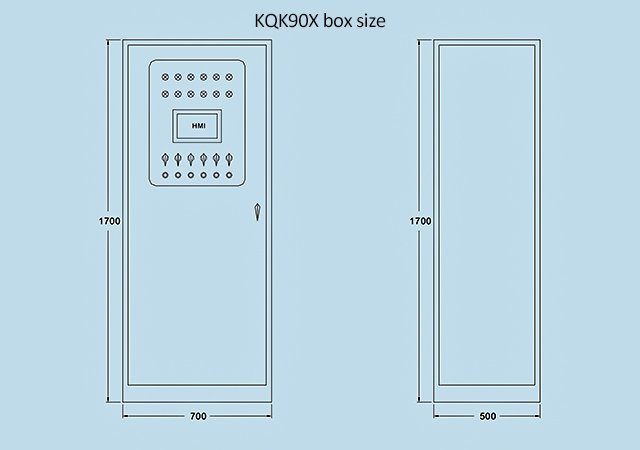

The KQK900 series control cabinet developed and produced by Kaiquan Company is used for supporting water supply equipment such as fully automatic diesel engine fire protection, production, and daily life. This series of products is fully functional, reliable, easy to use, sturdy, and beautiful,

The equipment is equipped with maintenance free batteries, 12V/200Ah. Depending on the capacity and starting requirements of the machine’s starting motor, different quantities of batteries can be equipped. To meet the personalized needs of customers, other brands and models of battery products can also be selected according to customer specific specifications.

According to the requirements of equipment power, fuel consumption, and operating time, various volumes of fuel tanks can be selected. Generally, emergency products are selected for 4-6 hours. Our company provides 50L-2000L fuel tank products of various specifications.

This series of diesel emergency water supply equipment can be equipped with 10kW-1500kW imported and domestic diesel engines of various series. Only some models are listed in the table. Our company can design and produce them separately according to user requirements to achieve flexible combination of flow and head. The company will continuously adopt new technologies and processes to improve product performance and quality. This table is for selection and installation reference only, and will be revised accordingly in case of changes.

| Comprehensive technical parameter table | ||||||||||

| Number | XBC Device Model | Traffic | Pressure | Water pump model | Diesel engine parameters | Tank | Storage Battery | |||

| L/s | MPa | Model | Power | Speed | Manufacturer | |||||

| 1 | BC5,4/1360-600M17S | 1360 | 0.54 | KQSS600-M17/508 | WD360TAB110 | 1100 | 1500 | Wudong | 2000L | 6-Q(W)-200=4 |

| 2 | BC8,5/1050-600M123 | 1050 | 0.85 | KQSS600-M12/580 | KTA50-P1645 | 1227 | 1500 | Chongkang | 2000L | 6-Q(W)-200=4 |

| 3 | BC6,4/611-500M12S | 611 | 0.64 | KQSS500-M12/485 | KT38-P830 | 584 | 1500 | Chongkang | 1000L | 6-Q(W)-200=4 |

| 4 | BC8/570-400M9W | 570 | 0.8 | KQSW400-M9/573 | KTA38-P980 | 664 | 1500 | Chongkang | 1500L | 6-Q(W)-200=4 |

| 5 | BC5,9/570-400M13W | 570 | 0.59 | KOSW400-M13/481 | KTA19-P700 | 470 | 1800 | Chongkang | 900L | 6-Q(W)-200=2 |

| 6 | BC5/560-400M13W | 560 | 0.5 | KQSW400-M13/470 | WD269TAB43L | 432 | 1500 | Wudong | 900L | 6-Q(W)-200=2 |

| 7 | BC6/558-400M13W | 556 | 0.8 | KQSW400-M13/481 | WD269TAB48L | 482 | 1500 | Wudong | 900L | 6-Q(W)-200=2 |

| 8 | BC7,5/500-500M128 | 500 | 75 | KQSS500-M12/485 | YC8TD840L | 580 | 1500 | Yuchai | 1000L | 6-Q(W)-200=2 |

| 9 | BC7,5/350-350M9 | 350 | 75 | KOSN350-M9/503 | WD269TAB41L | 418 | 1500 | Wudong | 700L | 6-Q(W)-200=2 |

| 10 | BC18,5/250-300M4 | 250 | 1.85 | KQSN300-M4/685 | KTA38-P1200 | 895 | 1800 | Chongkang | 1500L | 6-Q(W)-200=4 |

| 11 | BC18/204-300M3 | 204 | 1.8 | KQSN300-M3/738 | KTA38-P1300 | &B0 | 1500 | Chongkang | 1500L | 6-Q(W)-200=4 |

| Comprehensive technical parameter table(Supporting Dongkang) | ||||||||||

| Number | XBC Device Model | Traffic | Pressure | Water pump model | Diesel engine parameters | Tank | Storage Battery | |||

| L/s | MPa | Model | Power | Speed | Manufacturer | |||||

| 1 | BC15/7-DG25-50X3 | 7 | 1.5 | DG25-50X3 | QSB3.9-P50 | 36 | 2900 | Dongkang | 100L | 6-Q(W)-200=2 |

| 2 | BC40/7-DG25-50XB | 7 | 4 | DG25-50XB | OSB3.9-P115 | B5 | 2900 | Dongkang | 200L | 6-Q(W)-200=2 |

| 3 | BC60/7-DG25-50X12 | 7 | 6 | DG25-50X12 | OSB6.7-P160 | 120 | 2900 | Dongkang | 200L | 6-Q(W)-200=2 |

| 4 | BC21/13-DG46-30X7 | 13 | 2.1 | DG46-30X7 | OSB3.9-P80 | 60 | 2900 | Dongkang | 200L | 6-Q(W)-200=2 |

| 5 | BC30/13-DG46-30X10 | 13 | 3 | DG46-30X10 | QSB3.9-P115 | 85 | 2900 | Dongkang | 200L | 6-0(W)-200=2 |

| 6 | BC45/13-DG46-50X9 | 13 | 4.5 | DG46-50X9 | OSB6.7-P160 | 120 | 2900 | Dongkang | 200L | 6-0(W)-200=2 |

| 7 | BC55/13-DG46-50X11 | 13 | 5.5 | DG46-50X11 | OSB6.7-P200 | 145 | 2900 | Dongkang | 300L | 6-0(W)-200=2 |

| 8 | BC31.5/24-DG85-45X7 | 24 | 315 | DGB5-45X7 | QSB6.7-P200 | 145 | 2900 | Dongkang | 300L | 6-0(W)-200=2 |

| 9 | BC33.5/24-DG85-67X5 | 24 | 3.35 | DGB5-67X5 | OSB6.7-P230 | 170 | 2900 | Dongkang | 300L | 6-0(W)-200=2 |

| Comprehensive technical parameter table(Supporting Xichai) | ||||||||||

| 1 | BC15/7-DG25-50X3 | 7 | 1.5 | DG25-50X3 | 4DW91 | 33 | 2900 | Xichai | 100L | 6-0(W)-200=2 |

| 2 | BC21/13-DG46-30X7 | 13 | 2.1 | DG46-30X7 | 4DX21 | 70.6 | 2900 | Xichai | 200L | 6-0(W)-200=2 |

| 3 | BC40/7-DG25-50XB | 7 | 4 | DG25-50X8 | 4DX23 | 8B | 2900 | Xichai | 200L | 6-Q(W)-200=2 |

| 4 | BC30/13-DG46-30X10 | 13 | 3 | DG46-30X10 | 4DX23 | BB | 2900 | Xichai | 200L | 6-Q(W)-200=2 |

| 5 | BC60/7-DG25-50X12 | 7 | 6 | DG25-50X12 | CAB110/12 | 125 | 2900 | Xichai | 200L | 6-Q(W)-200=2 |

| 6 | BC45/13-DG46-50X9 | 13 | 4.5 | DG46-50X9 | CAB110/12 | 125 | 2900 | Xichai | 200L | 6-Q(W)-200=2 |

The KQK900 series control cabinet is a fully automatic electronic measurement and control system for diesel engine pump units controlled by a programmable controller (PLC) or microcontroller. The control screen, together with the diesel engine pump group, forms a highly automated centralized control system for the pump group. Its reliable operation, high measurement accuracy, and convenient operation can be widely used in various enterprises and institutions as an emergency diesel engine pump group system control (system) for fire protection, production, and daily life.

The KQK900 series control cabinet can be matched with various specifications and models of diesel engines. According to its core controller and other special requirements, it can be divided into three levels: economy type, standard type, and special type.

Economy type: using a dedicated controller developed by a microcontroller to achieve measurement and control, parameter display, and design .

Standard type: PLC is used to achieve measurement and control functions, and a text display is used as the human-machine interface.

Special type: Based on the standard type, switch to human-machine interfaces such as touch screens and computers, as well as other special configurations.

When the water pump unit receives a valid operation command, or the electric pump power supply system loses power, or receives a remote control start signal, the unit can automatically start and run. If one start is unsuccessful, the unit will undergo multiple automatic restarts.

The control cabinet has the following various alarm functions: startup failure alarm; Low oil pressure alarm; High oil temperature alarm; High cooling water temperature alarm; Overspeed alarm; Battery low voltage alarm; Fuel shortage indication alarm, with protection functions such as low oil pressure shutdown, overspeed shutdown, emergency shutdown, etc

The control system provides a remote start stop control interface and passive status feedback contacts such as “operating status”, “start failure”, “comprehensive alarm”, and “control power on”.

4) The gate can be installed by flipping left and right (equipped with hydraulic hoist)

The working gate adopts a flat sliding type, and the pump is installed horizontally on the gate. The pump opens and closes together with the working gate, and the hydraulic hoist performs the left and right flip switching action.

Usually, BC equipment requires an independent fuel tank, and the volume of the fuel tank is usually calculated based on the fuel consumption of the equipment during 4-6 hours of operation. The calculation formula is as follows:

Fuel tank volume (L)>Fuel consumption rate (g * Kw/h) × Rated power of diesel engine × Required continuous working hours/800

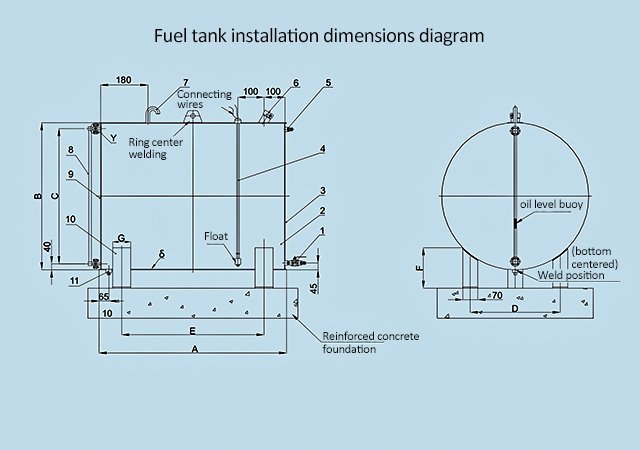

| Fuel tank model and specifications | ||||||||||

| Model | Fuel tank capacity | Oil storage capacity | A | φB | C | D | E | F | G | 8 |

| CYX50 | 50L | 52L | 530 | 360 | 250 | 200 | 350 | 300 | 100 | 2 |

| CYX100 | 100L | 103L | 665 | 450 | 350 | 250 | 450 | 300 | 100 | 2 |

| CYX150 | 150L | 155L | 750 | 520 | 400 | 300 | 520 | 300 | 100 | 2 |

| CYX200 | 200L | 205L | 850 | 560 | 450 | 350 | 570 | 300 | 120 | 2 |

| CYX300 | 300L | 308L | 950 | 650 | 550 | 400 | 620 | 300 | 120 | 2 |

| CYX500 | 500L | 544L | 1100 | 800 | 700 | 500 | 800 | 300 | 120 | 2 |

| CYX700 | 700L | 745L | 1250 | 880 | 800 | 550 | 950 | 350 | 140 | 3 |

| CYX900 | 900L | 925L | 1250 | 980 | 900 | 650 | 950 | 350 | 140 | 3 |

| CYX1000 | 1000L | 1036L | 1350 | 1000 | 900 | 700 | 1050 | 400 | 140 | 3 |

| CYX1500 | 1500L | 1527L | 1500 | 1150 | 1050 | 800 | 1100 | 400 | 140 | 3 |

| CYX2000 | 2000L | 2049L | 1500 | 1400 | 1300 | 900 | 1100 | 400 | 140 | 3 |

The equipment is equipped with maintenance free batteries, which usually require a cold start performance of 800A. Generally, two 12V, 200AH batteries are used in series for power supply. The series connection of batteries increases the voltage, but the capacity remains unchanged. The parallel connection of batteries increases the capacity, but the voltage remains unchanged. For high-power diesel engines, due to the high power of the configured starting motor, even two starting motors are equipped. In this case, a larger capacity battery pack is needed for power supply. Generally, four batteries are used, two in series and two in parallel. When using a dual battery starting circuit, In addition to doubling the number of batteries, it is also necessary to equip the control cabinet with two mains charging systems and automatic switching of two battery packs.

Attention: The supply and return oil pipelines between the diesel engine and the fuel tank are not within the scope of supply, and other pipelines, elbows, and variable diameter pipes of the exhaust system, except for corrugated pipes and silencers, are not within the scope of supply.

When lifting the diesel engine water pump unit, it must be lifted and moved horizontally as a whole, and tilting or dragging the water pump unit is strictly prohibited.

1.When installing the water pump unit, a thin iron sheet must be added between the metal common chassis of the unit and the foundation plane to level the foundation and the common chassis;

Please carefully read the accompanying documents of the water pump unit and strictly follow the operating and usage specifications specified in the “Diesel Engine Maintenance Manual” and “Diesel Engine Control Cabinet User Manual” to avoid human operation factors that may cause damage to the machine.

Please pay attention to the following points during equipment debugging and daily operation:

g.Fully open the inlet valve of the pump;

The foundation of the pump should have sufficient stiffness to support the pump and absorb vibration. The use of a concrete platform above the ground can prevent flooding of the unit and keep the site clean. The unit is fixed with anchor bolts, and the length of the anchor bolts is 15 times the diameter of the bolts. To better locate the unit, the reserved holes for the anchor bolts should be more than 4 times the diameter of the anchor bolts. Secondary grouting should be used, and each side of the foundation table should extend about 300mm beyond the unit base. A sewage pit should be set on the side of the foundation to collect oil and water dripping from the diesel engine.

Send Your Inquiry Today