The fire pumps in the Internet of Things fire water supply unit include vertical single-stage fire pump XBD-L-KQ series and new horizontal single-stage fire pump XBD-(W) series

Two pump types are available for users to choose. Both series of fire pumps have passed CCCF voluntary certification, and the pump performance meets the national standard GB6245-2006 “Fire Protection Pumps”.

Pump” and GB50974-2014 “Technical Specifications for Fire Water Supply and Fire Hydrant Systems” requirements.

The basic type of the Internet of Things fire water supply unit consists of two fire pumps forming a unit (one in use and one in standby). It can also be expanded according to actual working conditions.

Three fire pumps form a unit (dual use and one standby) or four fire pumps form a unit (three uses and one standby), suitable for indoor fire hydrant systems

fire water supply system, outdoor fire hydrant system, automatic sprinkler system or fire cannon fire extinguishing system. The design of ZY series fire booster water supply equipment fully utilizes

Taking advantage of the emerging technologies and mature experience of municipal water supply in recent years, combined with the development of Internet of Things technology in recent years, we developed and produced a new, multi-functional

Integrated, safe and reliable fire extinguishing facilities with good applicability.

2.1 Technical Specifications: GB50974-2014 《Technical Specifications for Fire Water Supply and Fire Hydrant Systems》

2.2 Product Standard: GB27898-2011 《Fixed Fire Water Supply Equipment Part 3 Fire Pressure Stabilized Water Supply Equipment》

2.3 Product standard: GB16806-2006 《Firefighting Linkage Control System》

2.4 Other standards: GB 50974-2014 《Technical Specifications for Fire Water Supply and Fire Hydrants》 Implementation Guide;

2.5 Reference standard atlas: 15S909 《Atlas of Technical Specifications for Fire Water Supply and Fire Hydrants》;

15S202 《Indoor Fire Hydrant Installation》;

01S105《Selection and installation of commonly used small instruments and valves》 ;

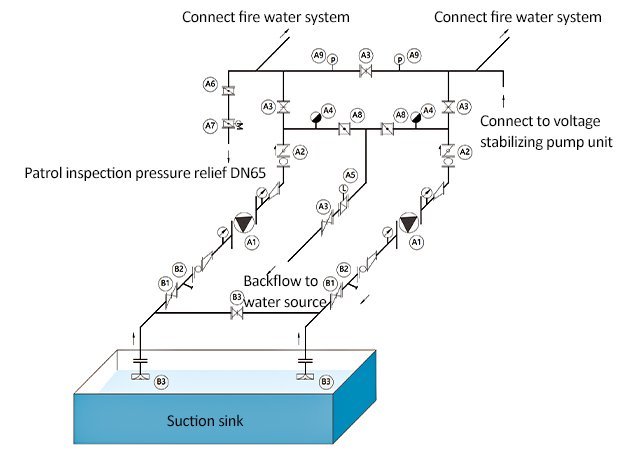

The Internet of Things fire water supply unit is composed of fire water pumps (including fire

main pump and fire backup pump), fire electrical control cabinet, and control Instrument composition. The basic structure diagram of the equipment is shown in Figure

The conventional product of the Internet of Things fire water supply unit is a water supply unit with two water pumps (one in use and one in standby) arranged centrally. The equipment schematic diagram is shown in Figure 1

Show:

| System | No. | Name | System | No. | Name |

| Fire Pump | A1 | Electric fire pump | Fire Pump | A7 | Electric butterfly valve |

| A2 | Silencing check valve | A8 | butterfly valve | ||

| A3 | Fire gate valve | A9 | Pressure Switch | ||

| A4 | Test plug | straw Connecting pipe | B1 | Fire gate valve | |

| A5 | Electromagnetic Flowmeter | B2 | Y type filter | ||

| A6 | butterfly valve | B3 | Swirl preventer |

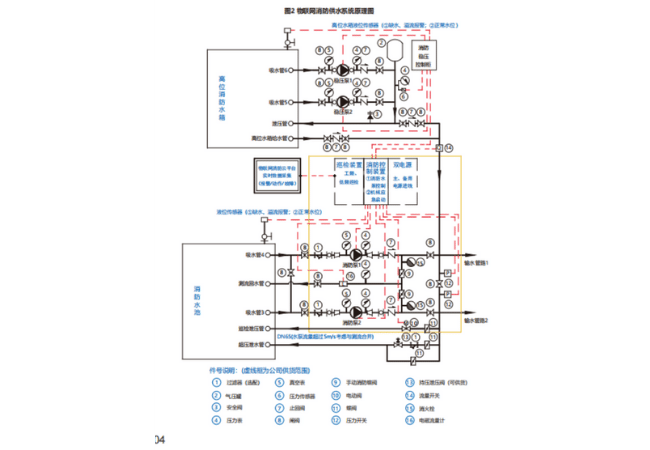

Part number description: (The dotted box is the company’s scope of supply)

1 filter (optional) 2 pressure tanks 3 safety valve 4 pressure gauge 5 vacuum gauge

6 pressure sensors 7 check valve 8 gate valve 9 Manual fire butterfly valve

10 electric valve 11 butterfly valve 12 pressure switch

13 Pressure-holding pressure relief valve (available)

14 flow switch 15 fire hydrants 16 Electromagnetic flowmeter

1.Special for fire protection, high reliability

The impeller is made of corrosion-resistant materials such as stainless steel.

Put an end to rust and ensure it can be started at any time

2.Compact and reasonable structure

The pump is directly connected to the motor and has a beautiful appearance.

Small footprint

3.All series obtained fire certification certificates

According to the requirements of fire protection regulations, the entire series has obtained

Fire certification certificate

4.Model optimization and reasonable distribution

The head distribution is reasonable and can meet the needs of different floors.

and pipe resistance fire protection needs

5.Newly designed according to fire pump standards

Fully meet the requirements of 1.5 times the large flow point head and

Power requirements

XBD series electric motor fire pump units (vertical single-stage fire pump, vertical multi-stage fire pump, new horizontal single-stage fire pump) are new products developed by our company based on market demand. Its performance and technical conditions meet the requirements of the newly promulgated national standards GB6245-2006 《Fire Pump》 and GB50974-2014 《Technical Specifications for Fire Water Supply and Fire Hydrant Systems》. The product has been certified by the Fire Protection Product Conformity Assessment Center of the Ministry of Public Security and obtained the fire protection certification (formerly CCCF compulsory certification, now voluntary certification).

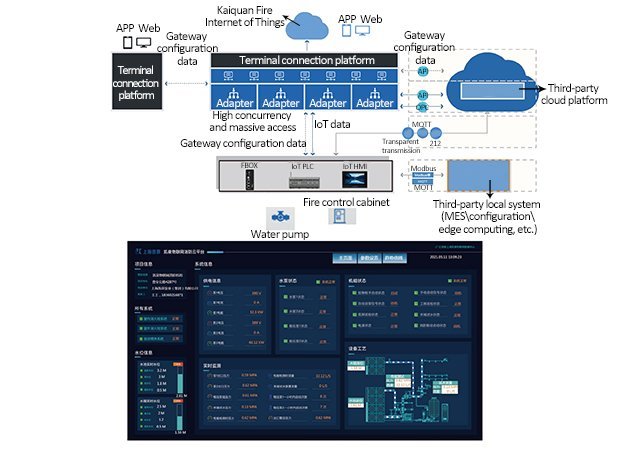

The fire electrical control cabinet supporting the Internet of Things fire water supply unit is a multi-functional combination control cabinet.

The specific functions are as follows:

| Fire pump control* | A component inspection | Historical data export function |

| Automatic power frequency inspection | On-site testing of water pump performance | Real-time data display |

| Automatic low-frequency inspection | Data storage function | Protection grade IP55 |

| Mechanical emergency starting device | Historical data query function | IoT data RS485 or Ethernet interface |

Note: Single pump power Pe ≤ 45KW means direct starting; single pump power 55KW ≤ Pe ≤ 160KW means star-delta reduced pressure starting.

According to the number of fire water pumps in the equipment unit, the Internet of Things fire water supply unit can be divided into one-use and one-standby type, dual-use and one-standby type, and three-use and one-standby type. The basic type is one-use and one standby type.

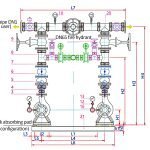

Equipment includes on-site test pipelines for fire pump performance (including flow meters and pressure testing devices), DN65 water test fire hydrants, each fire pump inlet includes an open-stem fire gate valve, soft joint, eccentric reducer, pressure gauge (vacuum gauge), etc. , the outlet includes concentric reducing pipes, pressure gauges, limited soft joints, check valves, rising pole fire gate valves, manifolds, maintenance rising stem gate valves and pressure detection components. The unit manifold contains safety valves and DN50~DN80 pipelines Interface (convenient to connect with the water outlet main pipe of on-site fire protection voltage stabilizing equipment);

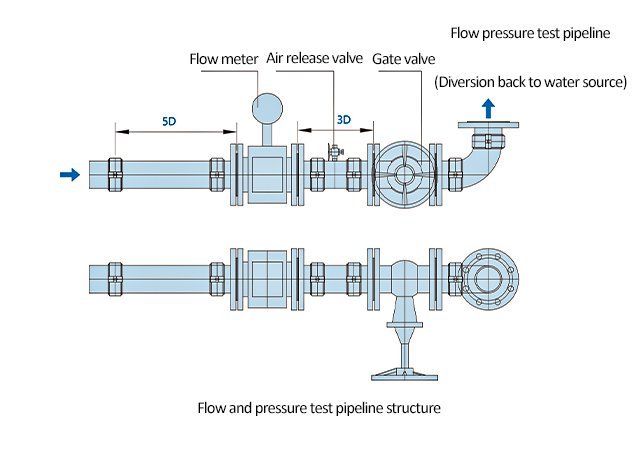

3.1. The flow and pressure test pipeline structure is shown in Figure 5.1.1:

Setting basis standard: GB50974-2014 《Technical Specifications for Fire Water Supply and Fire Hydrant Systems》

Chapter 5 Water Supply Facilities Article 5.1.11:

A group of fire water pumps should be equipped with flow and pressure testing devices in the fire water pump room, and should comply with the following regulations:

When the flow rate of a single fire water supply pump is not greater than 20L/s and the pressure is not greater than 0.5MPa, the pump set should reserve flow meter and pressure meter interfaces, and other pump sets should be equipped with pump set flow and pressure testing devices.

3.2. DN65 fire hydrant interface

Setting basis standard: GB 50974-2014 《Technical Specifications for Fire Water Supply and Fire Hydrant Systems》

Chapter 5 Water Supply Facilities Article 5.1.11 Point 4

A DN65 water test pipe should be installed on the outlet pipe of each fire water pump, and drainage measures should be taken.

3.2.1 Fire hydrant installation is based on GB 50016-2014 《Code for Fire Protection Design of Buildings》

Article 12.2.2 stipulates that when the dynamic pressure at the fire hydrant is greater than 0.5MPa, pressure relief facilities should be installed.

3.2.2 Fire hydrant installation basis: 15S202 Atlas 《Indoor Fire Hydrant Installation》

The atlas calibrates the model and main parameters of the pressure-reducing and regulated single-valve single-outlet indoor fire hydrant.

indoor fire hydrant

| Water pump head requirements | Indoor fire hydrant model |

| 70m≤water pump head≤160m | SNW65-Ⅲ |

| 50m≤water pump head<70m | SN65 single valve single outlet indoor fire hydrant |

| Water pump head<50m |

According to standard specifications: GB 50974-2014 《Technical Specifications for Fire Water Supply and Fire Hydrant Systems》 8.2 Pipeline Design

Article 8.2.9 stipulates that overhead pipelines should be connected by grooved connectors (clamps), threads, flanges, clamps, etc. Welded connections should not be used. When the pipe diameter is less than or equal to DN50, threaded and clamped connections should be used. When the pipe diameter is greater than DN50, groove connection or flange connection should be used. When the installation space is small, groove connectors should be used for connection.

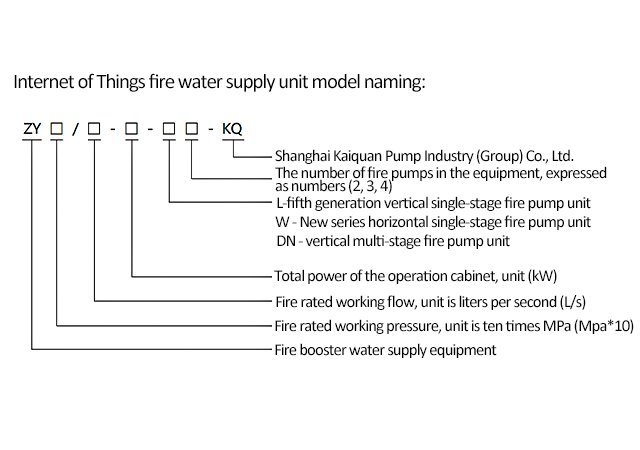

Internet of Things fire water supply unit model naming:

ZY □ / □ – □ – □ □ – KQ

Shanghai Kaiquan Pump Industry (Group) Co., Ltd.

The number of fire pumps in the equipment, expressed as numbers (2, 3, 4)

L – fifth generation vertical single-stage fire pump unit

W – New Series Horizontal Single Stage Fire Pump Unit display display display display display display display display display display display display display display display display display display display display display display display display display display display display display display display display display display display display display display

DN – Vertical multi-stage fire pump unit

Total power of the operation cabinet, unit (kW)

Fire rated working flow, unit is liters per second (L/s)

Fire rated working pressure, unit is ten times MPa (Mpa*10)

Fire booster water supply equipment

| Serial number | Name | Serial number | Name | Serial number | Name |

| 1 | Fire Pump | 8 | Manual fire butterfly valve | 15 | Pressure Sensor |

| 2 | Fire control cabinet | 9 | Fire rising pole gate valve | 16 | buffer tube |

| 3 | Flange with neck | 10 | Pressure Switch | 17 | Electric butterfly valve |

| 4 | Concentric reducer | 11 1 | Electromagnetic Flowmeter | 18 | Maintenance butterfly valve |

| 5 | Flexible rubber joint | 12 | Triangular release valve | 19 | 90° elbow |

| 6 | Silencing check valve | 13 | Pressure gauge/vacuum gauge | 20 | Trench tee |

| 7 | Grooved pipe joint | 14 | Three-way needle valve | 21 | Unit base |

The company’s Internet of Things fire water supply unit mainly promotes the standard fire pump as the new series of horizontal single-stage fire pumps. The fifth-generation vertical single-stage fire pump is an alternative model. Users can choose according to the needs of the on-site pump room.

The unit design scheme fully complies with the fire protection system design specifications, and the schematic diagram of the scheme is consistent with the water supply and drainage schematic diagram of the on-site pump room. There is no need for the design institute to modify the drawings for use. The unit’s inlet and outlet pipe network can be directly connected to the on-site fire pool water supply and the user’s fire ring pipe network. The complete set of supplied units is equipped with pipeline brackets that can be recycled and reused according to user needs.

The ordering of this product is not restricted by the performance parameters listed in the document. Our company can produce it according to the actual flow, lift, power and other parameters required by the project as well as different system types.

When pricing the unit CRM system, the total equipment model and supporting control cabinet model must be listed item by item under the same pricing order number. The total equipment model should include the fire pump unit model. The supporting control cabinet model is in parallel relationship with the overall equipment model.

If you have special requirements, please indicate them when ordering, and our company will produce them according to the actual situation.

When ordering, please provide the complete equipment model or basic parameters such as flow rate and head at the operating point required by the user.

Send Your Inquiry Today